Product Category

The company integrates the research and development, design, manufacturing, sales, commissioning and installation of heat treatment heating equipment, and provides customers with a complete set of mature heat treatment solutions. Product categories are muffle furnace, tube furnace, chamber furnace, atmosphere furnace, vacuum furnace, bogie hearth furnace, elevator furnace, drying furnace, mesh belt furnace, roller kiln, etc.

Hot Products

1200°C 12L Laboratory Atmosphere Muffle Furnace for Sintering

Tmax 1200℃.Carbon steel double sealed housing.Ceramic fiber chamber.Embedded HRE alloy coil wire heated. Shimaden PID temperature controller,programmable 32 segments.Installed with a 2-channel mass flow meters.

2-channel mass flow meters,flow rate adjustable

Multi gas inlet and outlet,Max 70000Pa

Work in inert or reducing gas mixture environment

1400℃ High Vacuum Heat Treatment Furnace PV L96/14

TMax 1400°C,Dual stainless steel sealed water-cooled shell,composite alumina chamber,SIC rod heated,Shimaden PID controller,programmable 32 segments.The furnace vacuum level could reach to 0.1Pa within 15 minutes.

Single float flow system, 1-10L/min freely adjustable

Suitable for a variety of atmosphere nitrogen or argon

An imported Roots vacuum pump and a set of PLC control program

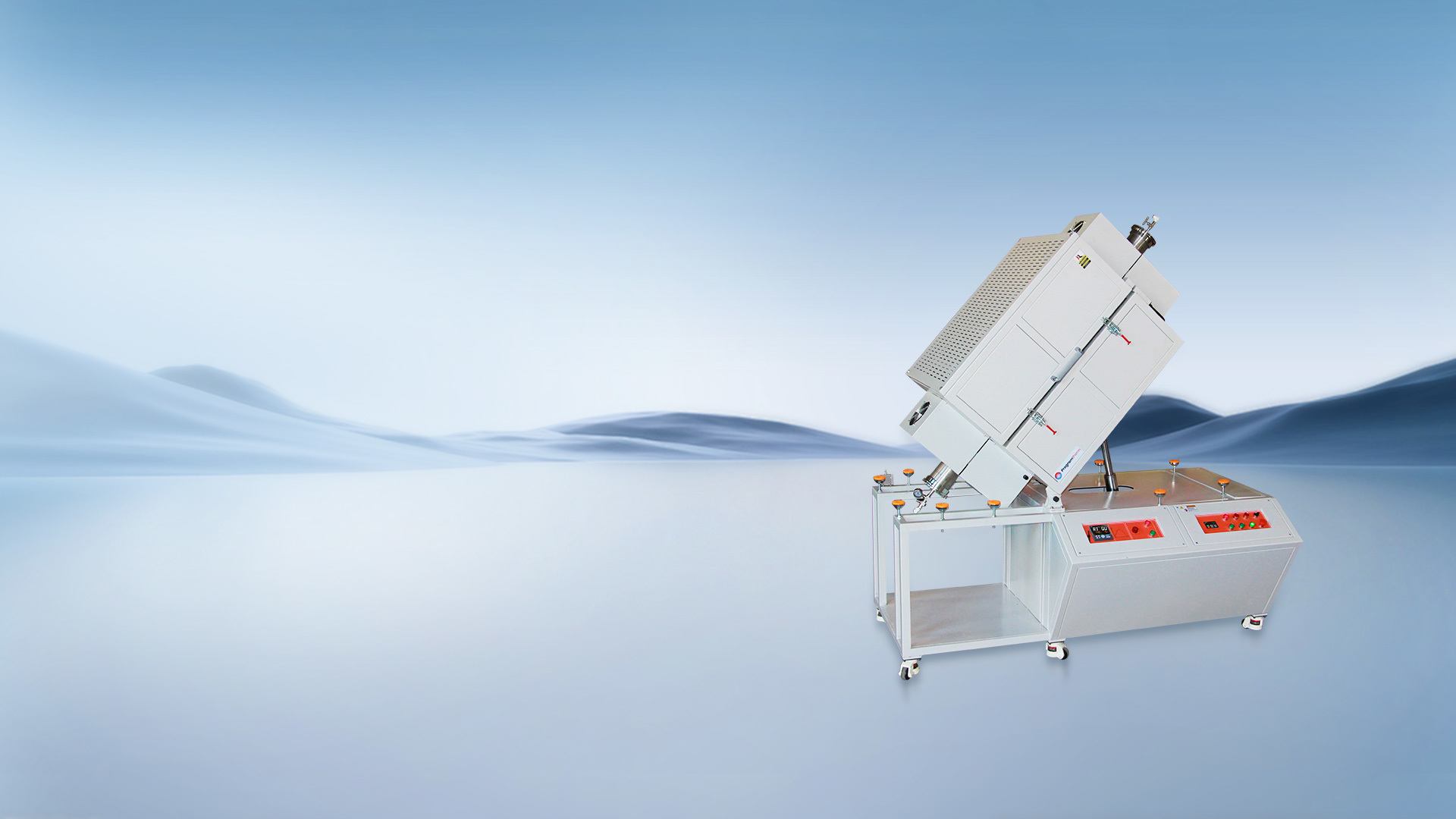

1200℃ Splitable Rotary Tube Furnace With Vacuum Pump

Single zone rotary tube furnace, high-purity polycrystalline alumina fiber chamber with HRE alloy coil wire.Suitable for annealing, diffusion and sintering under vacuum or atmosphere protection.

Rotary system, forward and reverse controllable

Single channel gas supplying system

Vacuum system,max vacuum degree 50Pa

1700°C Hydrogen Atmosphere Furnace With Ignition Device

Its structure consists of furnace shell,ceramic chamber,gas supplying,ignition system and temperature control system.Specially designed for material sintering or annealing in pure hydrogen or argon hydrogen mixed gas environment.

Float flow meter with flowing rate 1-10L/min adjustable

Automatic ignition device,controlled by PLC

Available gases:H2, Ar, N2 etc.

1600°C CVD High Temperature Vacuum Tube Furnace

CE certified CVD high temperature vacuum tube furnace, single zone, benchtop, non-opening and closing. Widely used in heat treatment under vacuum or atmosphere environment, CVD experiments etc.

Single-channel gas supplying unit,flow rate adjustable

Vacuum system,Max vacuum degree 50Pa

For CVD experiments,semiconductors etc.

1200℃ Manual Bogie Type Furnace 1000L

Industrial heat treatment manual trolley furnace.3 heating zones with 5-side HRE wire heating. Loading capacity up to 2 tons,enter along the track freely and safely. Mainly used for heat treatment for heavy and large steel parts.

Loading capacity 2 tons,move freely,load on four sides

Air circulation system,rapid cooling of the chamber

Exhaust discharging system,convenient for the discharge of smoke or exhaust gas

Why choose us

Program Thermal Tech

Export Orders

Exported Countries

Quality Assurance

CE certified, 18 months quality warranty, Free spareparts supplied within warranty period (excluded consumable parts)

Technical Team

Powerful technical team with 20 years experience in heat treatment industry, free customization

Manufacturing Capacity

Workshop covers 1500㎡. Products exported to Europe, America, the Middle East, Korea etc. 50 countries worldwide

Applications

Programtherm laboratory and industrial furnaces are widely used in various fields

In the chemical field, it's often used to synthesize high-purity materials, melt tests and catalytic reactions. For example, when preparing catalysts, calcining, activating, reducing or oxidizing the required materials can improve the activity and stability of the catalyst. It can also be used for heating and drying certain production processes in the chemical industry, and to manufacture materials required for high-temperature and high-pressure reactors, boiling dryers and other equipment. Electric heating furnaces play an important role in the chemical industry and provide important technical support for the production and research and development of chemicals.

查看详情In the aerospace field, it's mainly used for the refining and processing of high-temperature scrapped metal parts, as well as the direct production of materials such as steel, zirconium, titanium, magnesium, etc.; it can simulate the study of reverse carburization and photochemical effects in space; it can perform heat treatments such as quenching and tempering on aircraft engines and their components to improve their service life and durability, and at the same time it can detect whether the quality of components meets the standards.

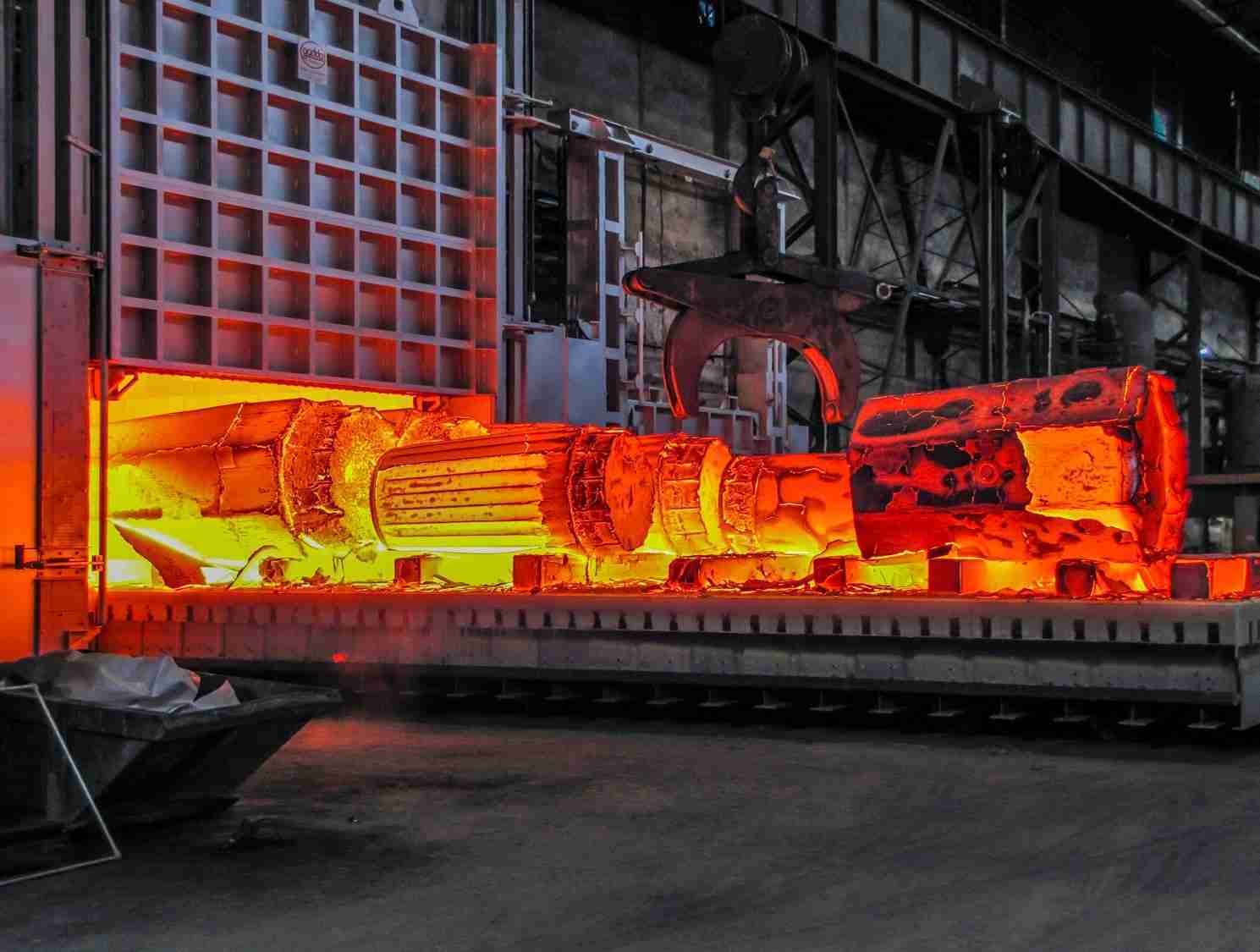

查看详情Suitable for heating and melting various metals, used in metal heating, melting, annealing, quenching and other processes, as well as manufacturing heat-resistant alloys and other high-temperature metal products. It can quickly heat metal at high temperatures and maintain a constant temperature to meet different process requirements.

查看详情Mainly used for heat treatment tests of materials, such as crystal recrystallization, annealing, homogenization, stress relief and other processes. These processes can change the structure and properties of materials and improve the strength, toughness, corrosion resistance and so on of materials.

查看详情Widely used in the synthesis process of lithium-ion battery positive electrode materials, which can provide a high-temperature environment with controllable oxygen content to ensure the purity and crystallinity of the materials; in the solar photovoltaic industry, it is used for the processing and treatment of silicon wafers to improve the efficiency and performance of silicon wafers; in the field of fuel cells, it is used for the manufacture and processing of battery stacks to ensure the performance and life of fuel cells.

查看详情In glass technology, it's used to heat glass materials, provide high temperature and constant heating environment, and make glass materials melt and shape quickly to make various glass products, such as glassware, glass fiber, etc., to meet the production needs of various glass products. At the same time, heat treatment of glass can change its physical properties, such as strengthening strength and improving wear resistance.

查看详情A common laboratory equipment, widely used in experiments and small batch production in colleges and universities, scientific research institutes. It is mainly used for heat treatment, sintering, degassing, annealing, burning and other processes of samples; used for powder roasting, ceramic sintering, high temperature experiments, material processing, quality inspection and other scientific research and teaching experiments, providing important experimental means for materials research, analytical chemistry, fuel analysis, geology and other fields.

查看详情It can sinter ceramic materials at high tems, provide a stable heating effect, ensure that the materials are fully sintered, adjust the grain size and phase change temperature of ceramic materials, improve the density and mechanical properties of materials, obtain the required physical and chemical properties, and ensure that the quality and performance of ceramic products meet the requirements. In addition, it can also be used for heat treatment of ceramic materials, such as vitrification and annealing of ceramics.

查看详情Access to business opportunities

In addition to the mentioned wide range of standard furnaces, our powerful engineer team also support customized services according to users' requirements.

Contact us now to buy our standard furnaces or customize your needed ones, programtherm furnaces surely make your heat treatments more successful!

Our Customers

80% orders exported to more than 50 countries worldwide

We have been working with some fortune 500 clients

Hotline

Testimonial

Sobin Williams

For annealing of metal steel parts in our plant, we ordered a turret bottom furnace model PB L660/12, the packaging was convenient and without damage, the oven design was very good, the manual trolley, easy loading and unloading, good test performance, the whole ordering process was very pleasant, thanks to the kind and professional service and of course the high quality of the product. We are looking forward to cooperating again in the near future.

Aarif Zaheer

The muffle furnace I ordered is great! I love the controller and how easy it is to use. The ordering process was easy and the furnace was packaged very well. Programtherm was a great partner and made sure I had everything I needed. I would highly recommend Programtherm furnaces to anyone who needs a quality furnace.

News

Focus on Programtherm furnaces, learn more about the industry news

What is the difference between a muffle furnace and a chamber furnace?

Chamber furnaces and muffle furnaces are two common heating equipments that differ significantly in many aspects.

2024-11-13

If any interests or questions, contact or leave us a message here, our professional sales will reach you soon.

Procurement consulting

The company integrates the research and development, design, manufacturing, sales, commissioning and installation of heat treatment heating equipment, and provides customers with a complete set of mature heat treatment solutions. Product categories are muffle furnace, tube furnace, atmosphere furnace, vacuum furnace, car furnace, lifting furnace, drying furnace, mesh belt furnace, roller kiln, etc.